In the current market, many automobile brands have launched three-cylinder models. Faced with the pressure of environmental protection policies and consumers’ requirements for fuel economy, more and more manufacturers will launch models equipped with three-cylinder engines. 2019 is the first year of the explosion of three-cylinder engines, and the position of small-displacement three-cylinder engines will become larger and larger in the foreseeable future.

Due to the congenital reason of odd cylinders, the first-order reciprocating inertia moment of three-cylinder engine is unbalanced, which is a word "shaking" in the actual driving experience, which is why many people talk about "three cylinders" and change their color. At present, the "three cylinders" at this juncture can be said to be a kind of engine form that is difficult to avoid. Then who can take the lead in doing the "three-cylinder" experience, who may seize the market first. A few days ago, Geely Automobile held an activity of "Binrui 200t 160,000km engine’s 100-hour crazy challenge with no limit" at Geely Power Research Institute in Hangzhou Bay, Ningbo.

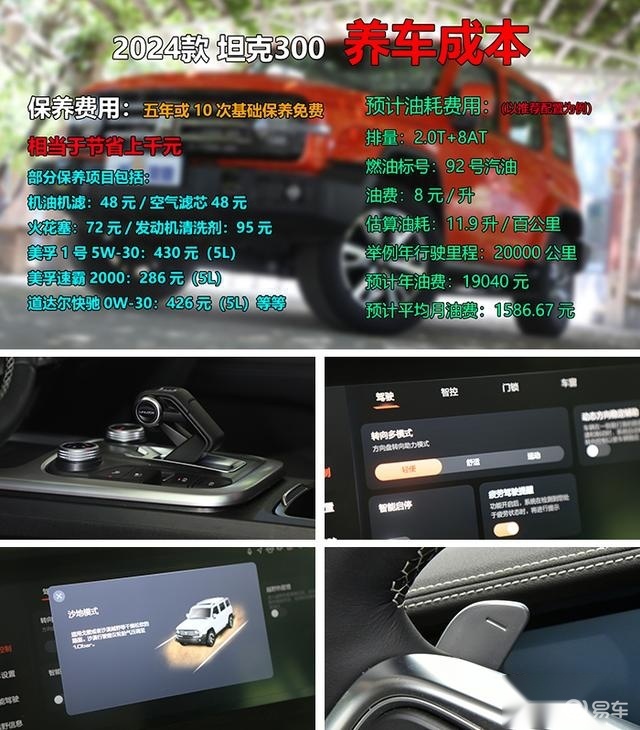

Through the form of disassembly+explanation, this paper shows how Geely builds an efficient three-cylinder engine without shaking. In fact, it is not easy to disassemble an engine that has been used for a long time in the eyes of many media, because as long as the engine is slightly flawed, it may be made public by the media.

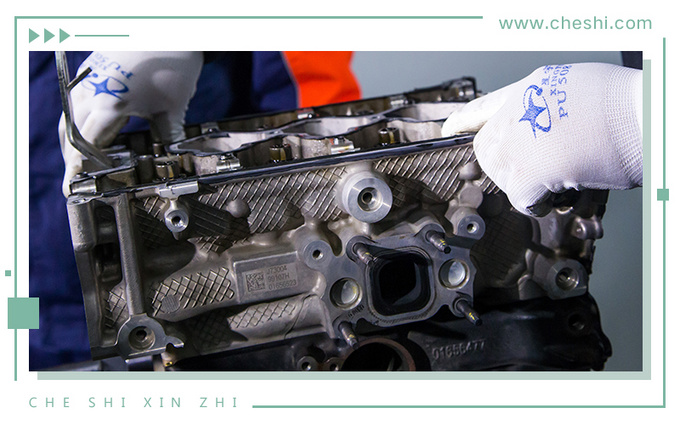

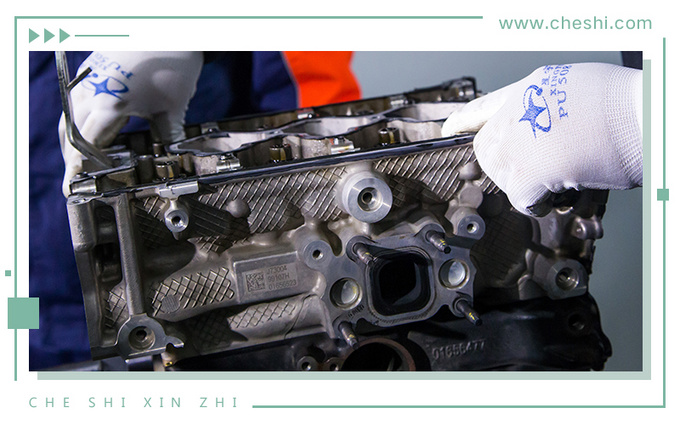

The engine disassembled by the technician has passed the 160,000-kilometer road test, the test of high fever, cold and harsh plateau environment, and then passed the 100-hour full-load operation test on the test bench. The simulation is the state of an engine after 8 years of use in the hands of ordinary car owners. Let’s analyze this non-shaking three-cylinder engine step by step from the cylinder head.

The disassembled engine model is JLF-3G10TDB, the cylinder head is made of aluminum alloy, and the integrated exhaust manifold design is adopted. At present, the purpose of the birth of a small-displacement three-cylinder engine is to "save energy efficiently". The integrated exhaust manifold can not only effectively use the exhaust temperature to help the engine warm up when starting, but also has advantages for the control of exhaust temperature and the normal work of three-way catalysis.

This engine is equipped with two thermostats, the "big" and the "small". The small thermostat controls the small circulation and controls the coolant to circulate in the cylinder when the engine is started. Together with the integrated exhaust manifold, this heat source can quickly make the engine reach the appropriate working temperature. When the engine is working normally, the coolant is connected to the large cycle of the whole cooling system.

Compared with the traditional external exhaust banana design, the integrated exhaust manifold can not only effectively utilize the waste heat generated by exhaust gas, but also shorten the path of exhaust gas to the turbine blades. With the small inertia turbine from Garrett, the 1.0L exhaust engine can still blow the turbine quickly, providing excellent response capability. In order to output a peak torque of 205Nm at 2000 rpm while ensuring the responsiveness, the designed maximum speed of this turbine reaches 290,000 rpm.

In terms of fuel supply system, this engine adopts direct injection in the overhead cylinder, which avoids the abnormal situation that the "wet wall" leads to the increase of engine oil. Continental has provided a 5-hole fuel injector for this engine, and the fuel injection pressure can reach 200Bar. Since the development of this engine began seven years ago, there is a certain gap compared with the 350Bar used in the latest engine, but we also learned from the conversation with engineers that Geely will continue to develop the second generation engine, and I believe that a higher pressure fuel injection system will be used at that time.

The cylinder body is made of cast iron. According to the engineer on site, compared with aluminum alloy, cast iron cylinder body has more advantages in shock absorption. This engine adopts the design scheme of 3mm thin cylinder wall, and the cylinder block of three-cylinder engine can usually be reduced by more than 50mm in axial length compared with that of four-cylinder engine. Therefore, thanks to the volume advantage of three-cylinder engine, the weight of cast iron cylinder block is still well controlled.

In the part of NVH management, Geely first put the engine in the semi-elimination laboratory, oriented the noise source of the whole power system through the microphone array conforming to SAE (International Society of Automata Engineers) specifications, and then analyzed the noise-emitting parts to improve the noise source.

Firstly, aiming at the silent design of belt and gear, in order to reduce the noise of gear and belt during transmission, Geely used composite materials between the alveoli of gear and used timing belt instead of timing chain to further reduce the noise of gear and belt during operation.

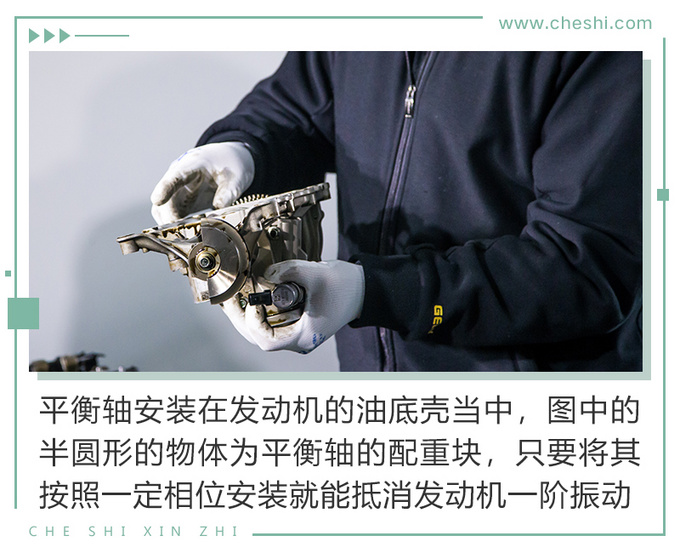

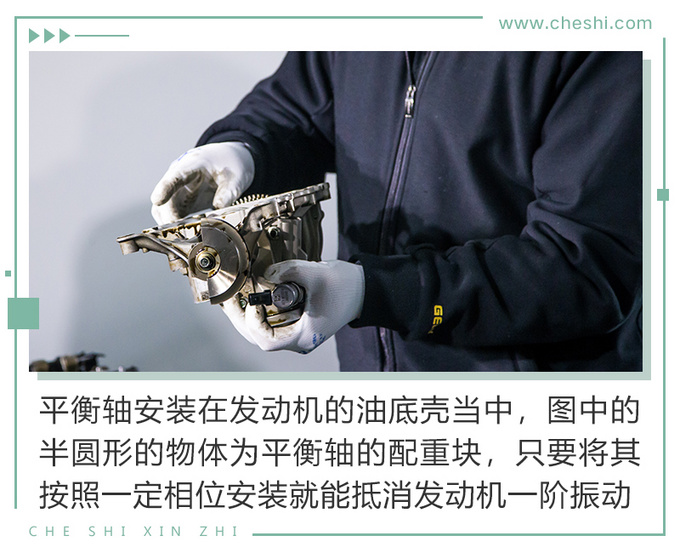

Geely introduced the "balance shaft" to suppress the vibration of the "three cylinders". One end of the balance shaft has a gear combined with the gear at the crankshaft end, and the first-order inertia of the engine is balanced by the design that the motion phase is opposite to the vibration. The whole balance shaft assembly is installed in the oil pan at the bottom of the vehicle. At present, there are many three-cylinder engines on the market, but not every one has a balance shaft.

Besides suppressing NVH of the engine itself, how to reduce the impact of vibration on the car body is equally important. Geely adopted a relatively traditional 3-point mount on the precursor of Binrui’s transverse engine. However, hydraulic bushings are used on both the left and right mounts. Compared with the practice of using hydraulic bushings only on the right side of traditional vehicles, it is obvious that the vibration isolation effect of dual hydraulic mounts is better.

In order to demonstrate the excellent NVH performance of this engine in an intuitive way, Geely engineers designed a "coin-standing" test. During the whole test, the coin did not fall down whether the engine was started or the speed was raised at idle speed. Although this is an engine test under no-load condition, it also reflects the NVH performance of Geely’s 1.0T engine under no-load condition. According to the on-site engineers, the displacement produced by the vibration of the seat slide rail in Binrui cockpit per second is only 0.35mm.

In the actual test drive, Binrui, which is equipped with a 1.0T engine, still can’t feel the vibration of the engine in the cabin under the load of four people. Trying to accelerate rapidly at the speed of 20km/h, the speed of establishing positive pressure of the turbine is almost the same as that of many larger displacement turbine engines, and the force exerted by the engine in the middle section is more rapid than that of the ordinary 2.0L naturally aspirated engine.

Because of the congenital reason of odd cylinders, the first-order reciprocating inertia moment of three-cylinder engine is unbalanced, which is the congenital defect of "three cylinders". I believe that even Newton’s old man could not wash the floor when he was alive. However, today’s engine technology has undergone earth-shaking changes compared with 20 -30 years ago, whether it is the accuracy of overall parts processing or the breakthrough in materials science. The change of the overall automobile industry environment has also made the "three cylinders" shoulder a more important mission. The "three cylinders" have reason to become better, and Geely has taken the lead in taking a solid step.

The 1.0T engine carried by Binrui is a brand-new product of Geely iNTEC technology brands, and it is the first 1.0TD engine independently developed by Geely. Through engine disassembly, we can see that it is not a product that blindly pursues "cheap". Geely’s intentions are reflected in the use of parts from internationally renowned suppliers and the design of NVH suppression. As early as 2010, Geely put forward the "technical Geely" strategy, and this 1.0TD engine is a microcosm of the "technical Geely" strategy.